When it comes to tech, Google has been synonymous with innovation, success, and world domination…

Answering 3 Key Automotive Industry 4.0 Questions

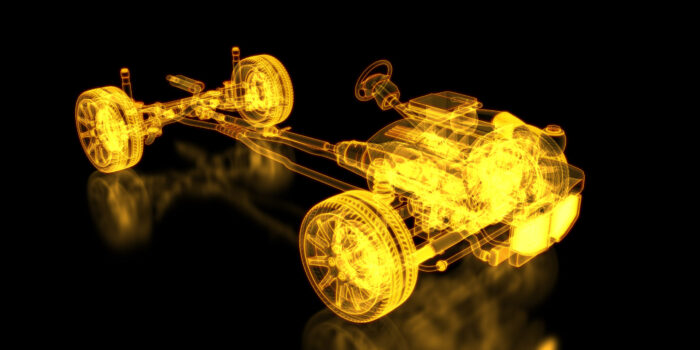

Vehicle factory shutdowns due to a microchip shortage, an automotive CEO losing his job for software concerns, and millions of connected cars on the road.

No doubt about it, Automotive Industry 4.0 is here.

Technology-related issues that weren’t a concern just five or ten years ago are now top of mind as customer demands and a rapidly changing industry push automakers and OEMs in new directions. Those changes bring incredible growth and innovation opportunities but can also be a source of uncertainty and turmoil.

Shifting Gears in Automotive Product Portfolio Management

From digitizing the driving experience to full-on automation, today’s automakers face challenges like never before. But today, exception is now an expectation.

To stay competitive and boost sales, a growing number of automakers are prioritizing Connected, Autonomous, Shared, and Electric (CASE). By 2025, connected vehicles will account for 53% of cars on the road, a number expected to reach 77% by 2030.

Several challenges stand in the way of this widespread innovation. But for companies with the right tools and forethought, these challenges are chances to create a competitive advantage. To see those benefits, automakers must strategically invest and ensure decisions align with their business goals. And this all needs to happen faster than ever before.

Tackling CASE and IoT auto innovations with speed requires product portfolio management insights that do the following:

- Understand the ROI of R&D efforts to know where to best focus investments.

- Pinpoint investment opportunities that connect software development’s best practices to speed production.

- Provide real-time data of the entire portfolio lifecycle to know when to stop, speed up, and pivot.

The tricky part is that this must all occur regularly and simultaneously — from innovation prioritization to planning, execution, and in-market analysis — to ensure accelerated investments meet market demand.

To reach this point, automakers need to understand the answers to three critical questions:

How Can Companies Balance R&D Costs with Innovation?

Innovation is synonymous with the auto industry. U.S. automakers and their suppliers are the world’s third-biggest innovators in R&D, with investments of around $130 billion annually.

But in the competitive market, companies can’t afford to invest in the wrong areas or miss their launch dates. Accuracy in portfolio prioritization is crucial. Investing in the wrong product pipeline can sink an entire company, forcing leaders to make weighty decisions that could transform their companies. Some companies are even considering exiting entire vehicle segments that aren’t profitable so they can afford the higher cost of R&D for connected cars.

Automakers need a robust product portfolio management solution to prove the feasibility of business goals and show the ROI of potential innovations.

Suppose a company wants to focus on markets with regulations that support the rapid commercialization of autonomous vehicles and allow for faster market growth. A portfolio management solution can collect, categorize, and analyze market data to pinpoint the largest growth opportunities. Automakers and OEM companies can also use that data to defend or negate an automotive company’s R&D strategy.

R&D isn’t its own entity but should be woven centrally into the organization’s mission. Automakers need a solution to make the best R&D choices and ensure critical efforts are aligned with corporate strategy and offer a strong ROI. With the proper support and tools, R&D can highlight a company’s disruptive breakthroughs and innovative opportunities.

How Can Automakers Leverage Cross-Functional Teams to Ensure Resource Allocation Speeds Up Production?

These days, the car is a mobile device. And with that mobile and connected focus comes a need to apply agile software development principles to a company’s product development strategy.

But many OEMs’ efforts to apply software development principles are hindered by siloed teams, disconnected workflows, and a lack of system integration. Many automakers also feel pressure from agile technology companies that already have in-house software expertise, further complicating matters. But the reality is that in most cases, end-to-end EV production for a single automotive company can take a toll on resources and present many challenges, making the entire endeavor inefficient.

Organizations that find themselves in this difficult position often find success in solutions that support the integration of software expertise or by partnering with other organizations that specialize.

A cohesive internal strategy begins by integrating the principles and methods of software development with existing workflows throughout the company. The goal is for the software developers and mechanical engineers to speak the same production language and use the same processes. With that foundation, it becomes easier to make informed decisions to invest in infrastructure that supports a cross-functional production strategy that promotes collaboration, visualization, speed, and overall efficiency. The product portfolio solution becomes a real-time resource to consolidate and visualize the workflows and expenses of cross-functional teams.

Through integration, teams can plan and execute quickly and efficiently. Much like those agile technology companies, ensuring cross-functional teams are working at their highest potential requires constant adaptation and evaluation.

How Can Companies Increase Visibility to Combat Supply Chain Issues?

Understanding R&D investments and workflows are only part of the process — the success of connected cars is increasingly dependent on acquiring the needed materials.

The recent microchip shortage brought automakers to a near standstill and is a prime example of the need for visibility into potential material and supply chain issues. Construction of factories, labor shortages, and machine and operational issues are all potential risks companies need to consider in their EV product development portfolios.

Automakers may not be able to prevent supply chain issues, but they can avoid their negative impact by relying on technology to break down silos, improve visibility, and share data across the company, especially in a constantly changing market.

A product portfolio management solution consolidates supply chain data in one area to model scenarios and clearly identify risks and opportunities. And it’s not limited to one area of production — comprehensive product portfolio road mapping incorporates every step to get a vehicle to market and links milestones and key components to avoid missing launch dates.

Auto Industry 4.0 Offers Unprecedented Opportunities

The market is shifting, and consumer demands are evolving along with technological advancements.

Knowing which innovations to prioritize and being able to adapt and evolve quickly is crucial to every automotive company.

Whereas traditional automotive product portfolio management models were rigid, the industry’s push for CASE and IoT-connected vehicles requires agility and flexibility. While this move brings challenges, there are even greater opportunities for a strategic shift. Taking hold of those opportunities requires a willingness to embrace a more adaptive approach to product portfolio management.

By adopting a solution that allows auto companies to become more flexible, they can better prioritize Industry 4.0 innovations that ensure they focus on products that align with organizational goals and offer the best ROI. The most successful companies leverage product portfolio management tools to create a comprehensive strategy, from cross-functional data collection to extensive analysis, for a complete picture of the market, the company, and the competition.

With the unprecedented speed and challenges of the future come incredible opportunities for automakers willing to shift their perspective and adopt tools that offer foresight through market intelligence.

Watch our demo to see how your auto company can accelerate development and maximize ROI on Industry 4.0 innovation.

Source link

Comments (0)